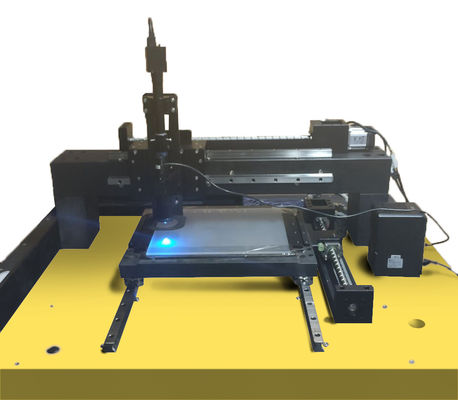

Glass Substrate Surface defect detector

Applications

For the process control and yield management of glass substrate manufacturing, we can help manufacturers to

identify and monitor the mask defects, reduce the risk of yield and improve their independent ability of R&D for

core technologies.

Working Principle

Using specific angle ring light, coaxial light source and running mechanism to collect and analyze the directional

photography information, thus realizing automatica detection for the defects on the glass substrate surface.

Features

| Model | SDD-GS-X—X | |

|

Performance detection |

Detectable defect type | Scratches, Dusts |

| Detectable defect size | 1μm | |

| Detection accuracy (measured) |

100% detection of defects / collection of defects (scratches, dust) |

|

| Detection efficiency |

≤10 minutes ( Measured value : 350mm x 300mm Mask) |

|

|

Optical System Performance |

Resolution | 1.8μm |

| Magnification | 40x | |

| Field of view | 0.5mm x 0.5mm | |

| Blue light illumination | 460nm, 2.5w | |

|

Motion Platform Performance

|

X, Y two-axis motion Marble countertop flatness: 2.5μm Y-axis Z-direction runout precision: ≤ 10.5μm Y-axis Z-direction runout precision: ≤8.5μm |

|

| Note: Customized production available. | ||

Detection Images

![]()

Our Advantages

We are manufacturer.

Mature process.

Reply within 24 working hours.

Our ISO Certification

![]()

Parts Of Our Patents

![]()

![]()

Parts Of Our Awards and Qualifications of R&D

![]()

![]()